Solution

To help the client gain deeper insights from historical drilling activities, Provectus designed and deployed a comprehensive enterprise solution, combining an Integrated Energy Data Platform (IEDP) with a custom GenAI application built on top. Recognizing the fragmented nature of upstream data across SCADA systems, Excel logs, and other siloed sources, Provectus developed a foundational data layer aligned with OSDU principles. This advanced IEDP enabled seamless ingestion and unification of diverse, structured and unstructured data at scale, which allowed the client to easily access and apply AI & GenAI-driven insights across the organization, unlocking a new level of drilling intelligence for the operational planning process.

With this architecture in place, Provectus moved to implement the GenAI capabilities in close collaboration with domain experts. At the core of the GenAI solution was a domain-specific large language model (LLM), carefully selected through the testing process, to process legacy drilling reports without disrupting existing reporting workflows.

Our work entailed:

- Calibration and validation of the model outputs together with drilling experts, ensuring operational credibility and eliminating noise.

- Automated event extraction from unstructured DDR text using a GenAI engine calibrated for 13 drilling risk categories (e.g., stuck pipe, circulation losses, equipment failure)

- Insights generation that enabled cross-well trend analysis and detection of recurring inefficiencies.

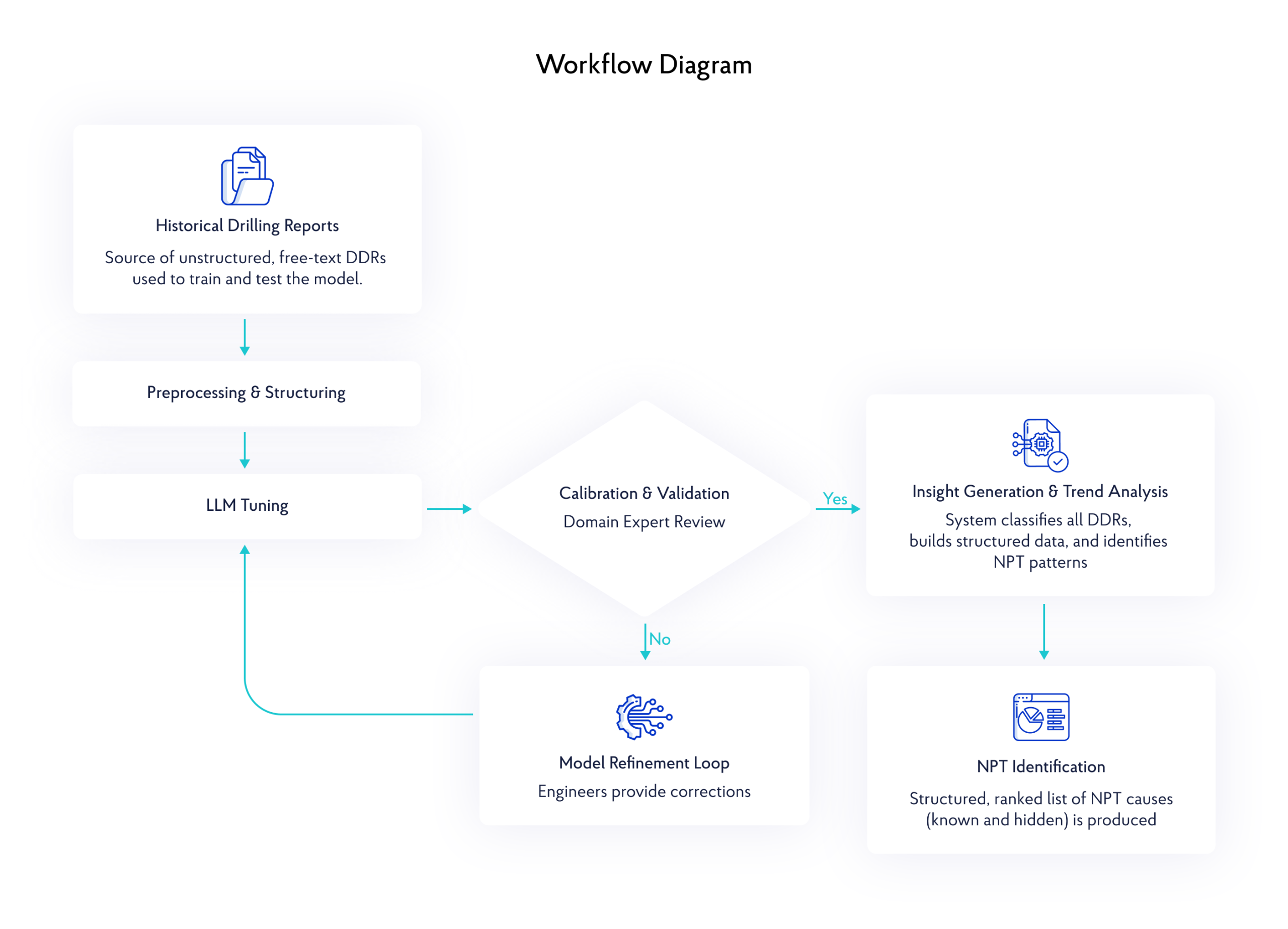

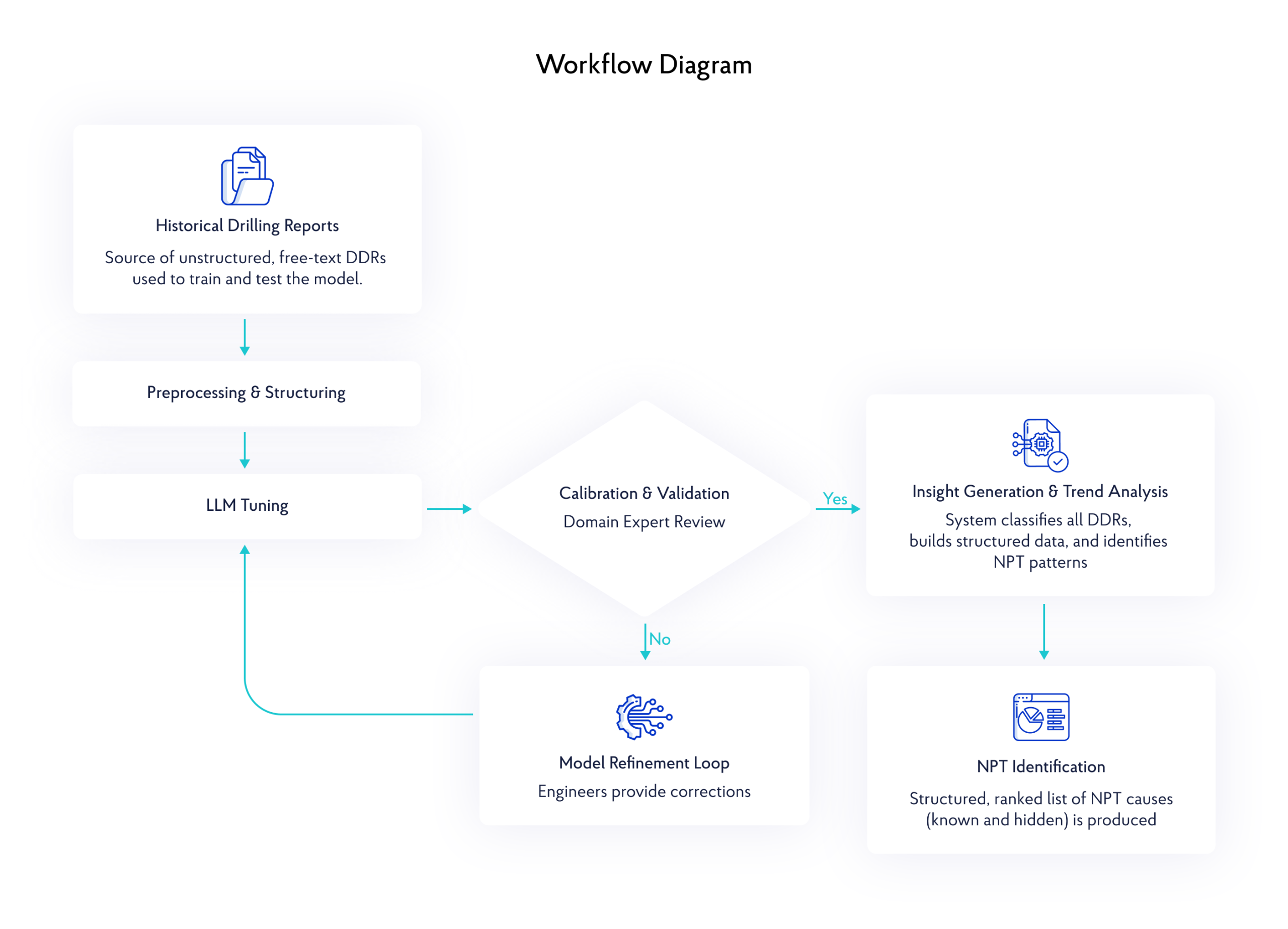

The Workflow Diagram illustrates the key stages of the LLM-driven analysis. The process began with the collection of historical DDRs, which served as the core data source for model training and validation. These reports were then cleaned, segmented, and structured into machine-readable units, unifying abbreviations, inconsistencies, and NPT-specific language.

Next, the preprocessed dataset was used to fine-tune the domain-adopted LLM. The initial outputs, including tagged events, durations, and root cause annotations, were reviewed by the client’s drilling engineer experts. Their feedback was incorporated into an iterative loop to further calibrate the model and improve tagging precision. The system processed over 1,500 DDR entries, with more than 94% alignment to expert-labeled classifications.

Once validated, the model was used to run full-scale classifications. It automatically identified the dominant NPT categories, as well as their duration, frequency, and context across wells or campaigns. The final outputs were used to support drilling performance reviews and planning decisions for the next drilling campaign, transforming static retrospective reports into a dynamic decision-support asset.

The solution was delivered as a highly scalable, cost-effective platform, designed and built using a range of AWS services. It enabled the client to accelerate drilling analysis workflows while storing produced outcomes and recommendations in a unified, cloud-based data warehouse for future use.

.png)